Recently I was helping my brother move, and he gave me a broken PMC-05 ProII mixer. It didn't power on, and it was missing all the knobs and the top (gold-colored) faceplate.

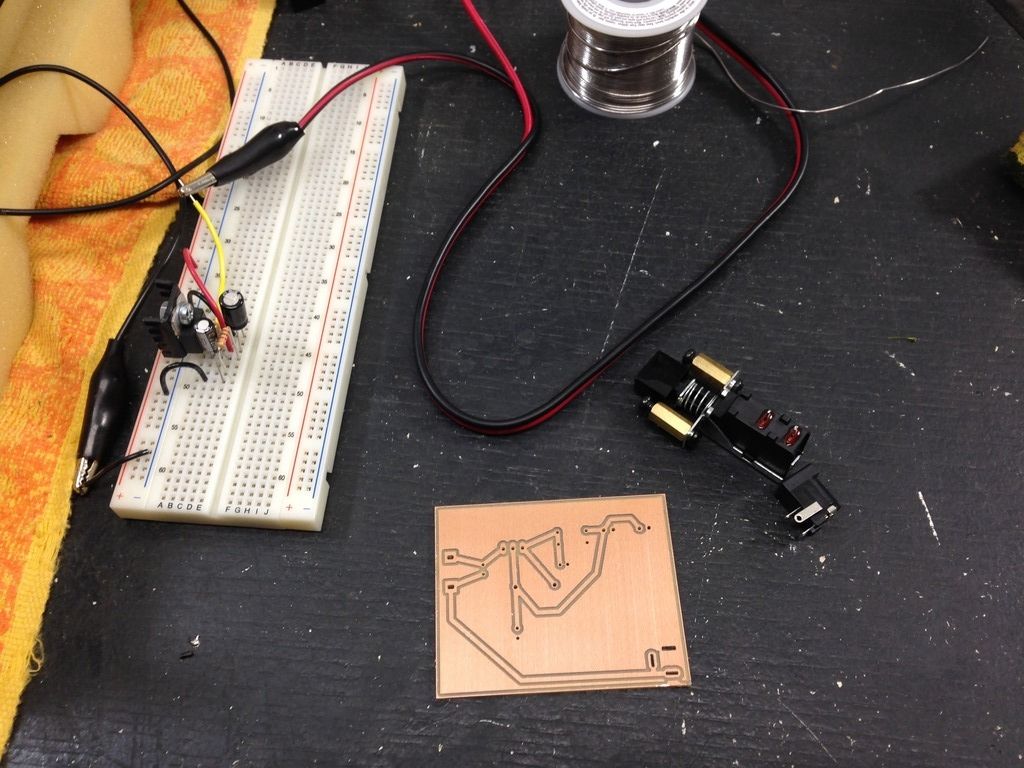

The first order of business was figuring out why it wouldn't power on. A little testing with a voltmeter told me that the power regulator board wasn't supplying any significant voltage to the rest of the electronics, so I began working on a replacement. I decided to use a single adjustable voltage regulator instead of the opamp-based voltage reference design originally used, because I already had the necessary parts.

The mixer being powered by the new design (on the breadboard), with the inoperative original board on the right

Having verified that the mixer worked fine with the new regulator design, I designed a PCB to hold the new design. I wasn't able to obtain a replacement switch that matched the original, so I removed the original switch from the old board and re-used it.

The PCB for the new design with the old switch and a new power jack

It fits!

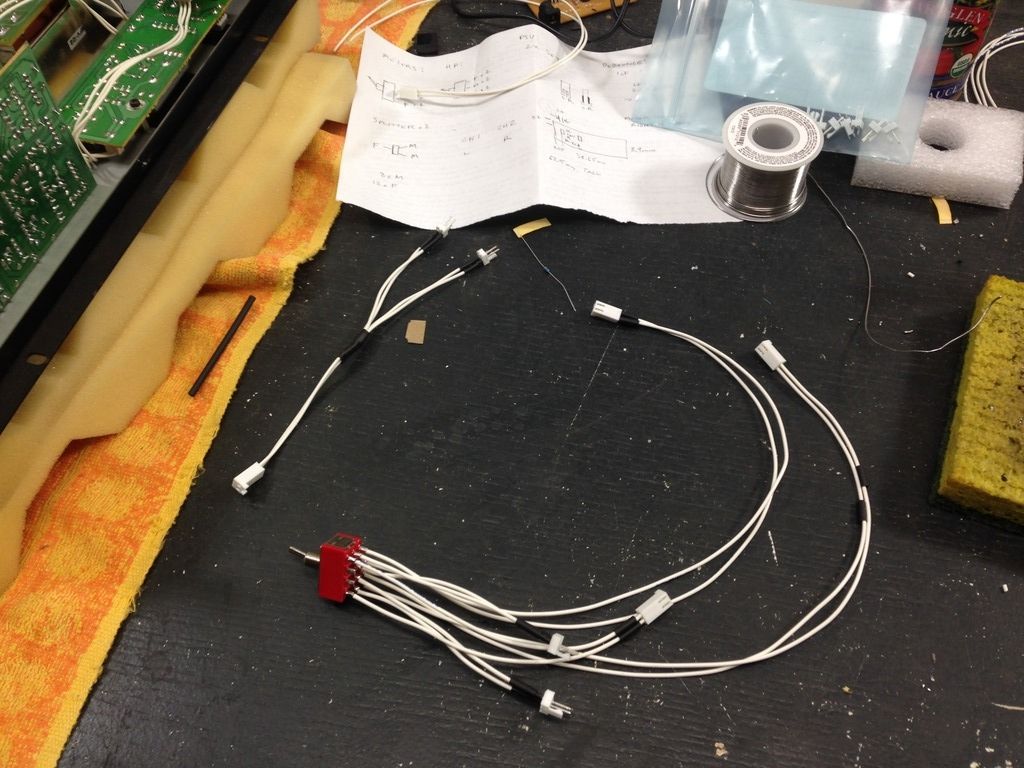

While I was working on the power supply, I noticed that the mixer internals were configured in such a way that I could fairly easily modify the monitor section and meters to switch between their default (per-channel) inputs and inputs from the master section of the mixer. In order to make this mod, I needed to add some leads to the master section PCB, make a splitter cable, and wire a couple of 4PDT switches.

Splitter cable and one of the switches

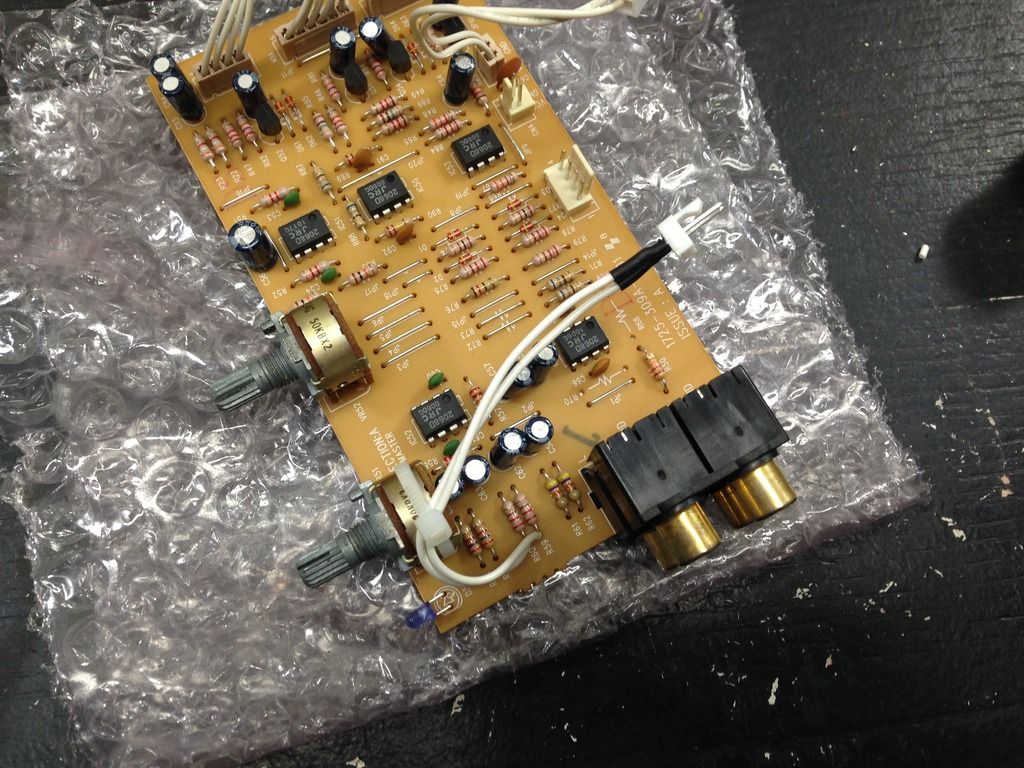

While I had the master section PCB out of the mixer, I decided to replace the red LED with a blue one.

Master PCB with new leads (zip-tied to a potentiometer for strain relief) and blue LED

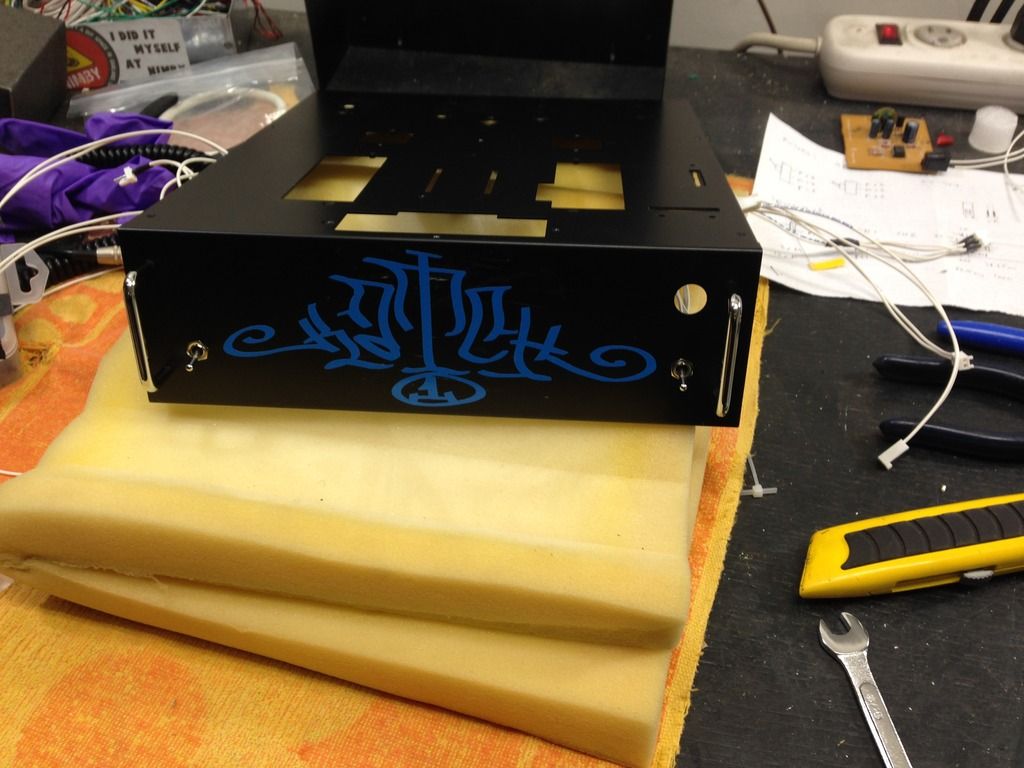

I decided to mount the new switches on the front panel of the mixer; I also decided to add small handles to the front to protect the new switches. I made a template to make sure the holes would be evenly spaced, then removed all the components from the top part of the case.

The top case ready for drilling

Switches and handles mounted

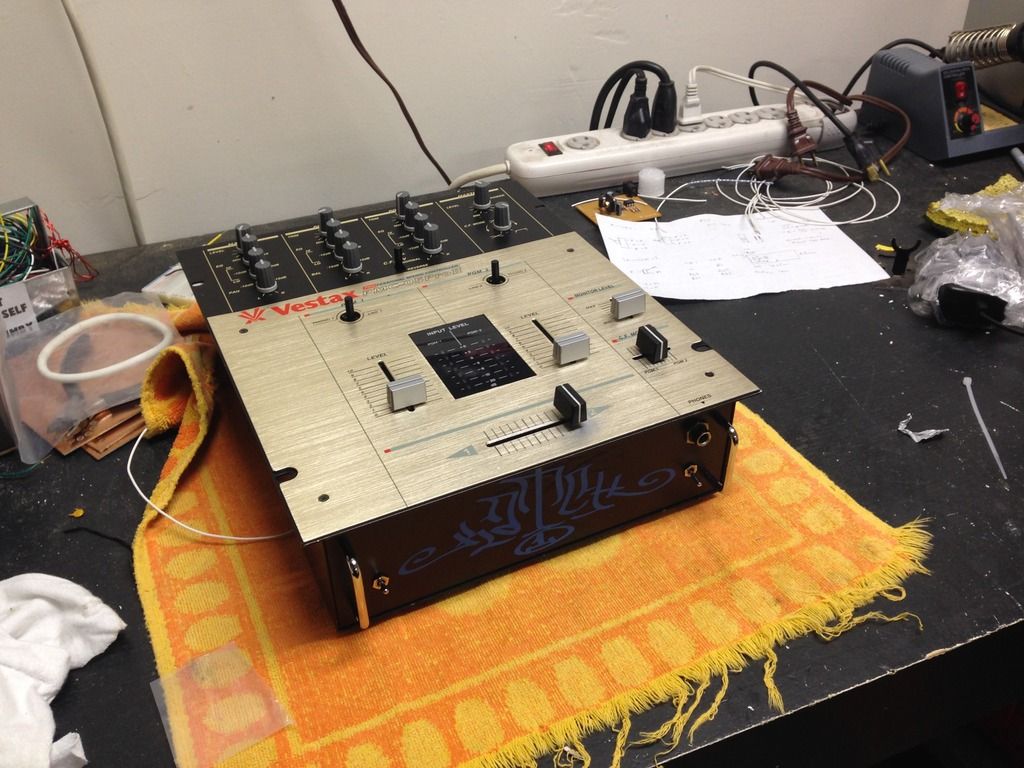

Everything reassembled

For the finishing touches, I bought a used replacement faceplate on eBay, and some rubberized knobs from an electronics store.

All done!

Reply With Quote

Reply With Quote

Bookmarks